You Got It!

Be a Kote Expert:

Making Kote with Kote Craftsman

How much do you know about making kote? How much do you care about your own kote and other kendo equipment? Can you tell the good equipment from the bad?

Let’s Become a Kote Expert

When I visited Shogun Kendogu, I happened to see Mr. Sugimoto fixing a kote. What you see in the video is Mr. Sugimoto sewing the tenouchi to the kote.

By this visit, I learn far more than I expected and I am glad that I can share what I learned with you now.

1st Step: Take a Good Care of Kote

Firstly I’d like to share good tips to take care of your kote. These are easy for you to do.

1. Clip Your Nails.

Many kendo practitioners don’t notice these rips when they wanted the tenouchi changed. So these kote craftsmen patch these holes first and start fixing the kote. They don’t charge for this extra effort.

Patched Kote during the Kote Fixing Process

Patched Kote during the Kote Fixing Process2. After training, you should

- Use tenugui or a towel to get rid of sweat from the tenouchi

- Smooth out the tenouchi (leather will shrink)

- Make a good grip and dry your kote in the shade with good ventilation. * No hair dryer (or laundry dryer)!

An Effort of Kote Craftsmen

There is something Shogun Kendogu is doing so kendo practitioners can keep our kote longer.

They use a special needle to sew kote. The normal needles for kote are very sharp. But because of that, they also cut fibers of kote materials. It is ironic because they are hurting the materials at the same time as fixing it.

Cutting a String with Sankaku-Bari

Cutting a String with Sankaku-BariSo they use a special needle. It doesn’t cut materials while fixing/making kote. It might seem like a not a big thing but I now appreciate their concern as kote craftsmen. I appreciate this type of attention from specialists.

I still remember what they said.

“Our wish is that people can use their kote longer”

Kendo equipment is not cheap. Not only it is not cheap, there is another reason.

Quick Fact: How many kote do you think one kote craftsman can fix per day? Just fixing kote all day long…

6 at most, if things go smoothly; no patching holes inside kote and so forth.

4 or 5 kote per day is more realistic. That is only ONE pair per day!

This is a fact that I thought I should share with you. If we keep them from fixing our kote all the time because we don’t take a good care of our kote, they can focus on making good quality kote. So let’s do our part!

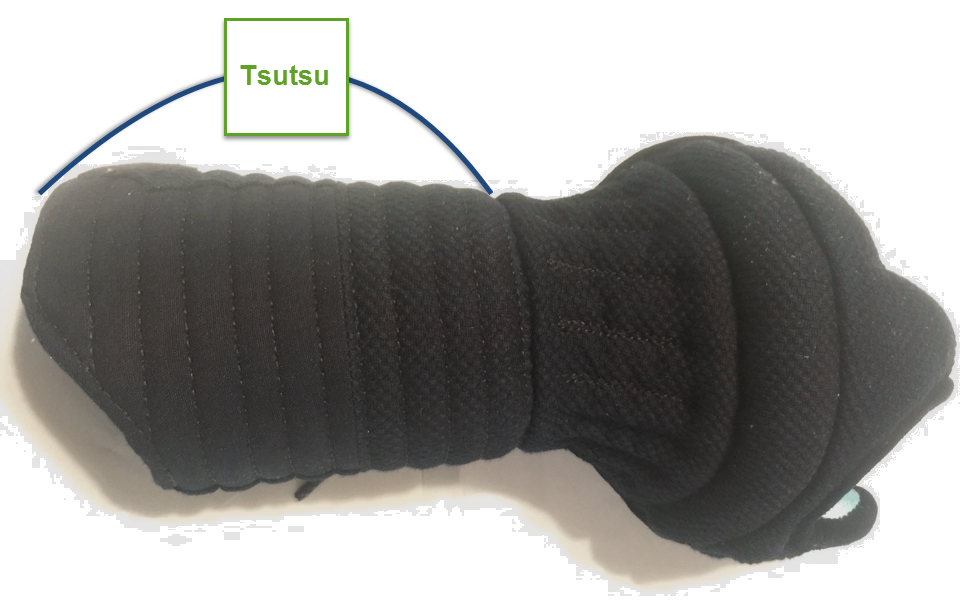

Tsutsu of Kote and Why Does it Have Stitches?

Did you watch the video? You can hear how surprised I was when I saw how thick it is. They say it is about 1.8-2cm (0.71 inch to 0.79 inch).

Thick Futon for Kote Tsutsu

Thick Futon for Kote TsutsuThis material will be the tsutsu part of your kote. The tsutus is where people hit and so it is one of the parts that we shouldn’t neglect. We want it to be thick to absorb the impact.

To Make It Absorb More Impact

It is very thick so you might think that it is good enough to protect our body. Actually it is not good enough.

To make it absorb more impact, they sew the material either by hand or sewing machine.

Can you see the stiches on the tsutsu part? By sewing the tsutsu material or futon, they make bumps on the tsutsu to absorb more impact. It is pretty brilliant, isn’t it?

The stitches of the kote in the photo are done by machine. We call it mishin-zashi. Mishin was named by how it sounded to the Japanese, ref: Wikipedia Japan. And zashi is originally sashi (refer to Wikipedia for the reason of changing “s” to “z”), which is a noun form of a verb, sasu (to stitch).

But as said in the video, since they use a good interlining, even the machine stitch can give us a good protection.

The tezashi (hand stich) is a lot better than the mishin zashi. Why is that? Click here to go to “Differences between the hand stitch (tezashi) and machine stitch (michin zashi).

Send a Message or Question to

Shogun Kendogu

They want to connect those who really appreciate handmade kendogu.

Send a message to support them or a question about their bogu using the form below.

I am sure they will appreciate your message. It is always glad to know that there are supporters out there.